Let us first define to you what Low-Cost Country Sourcing or LCCS is.

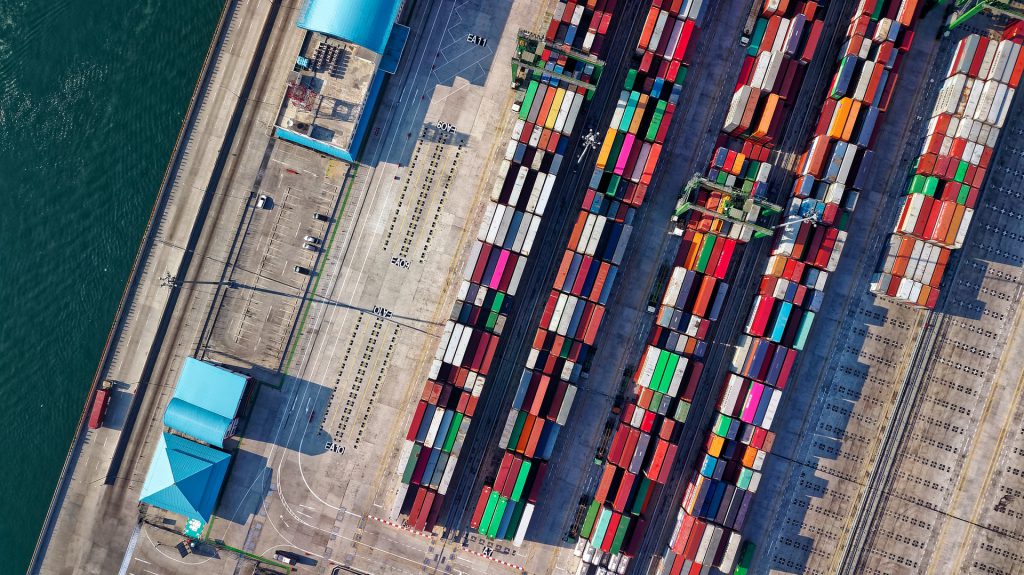

Low-Cost Country Sourcing or LCCS is the process where the procurement of goods and services such as raw materials, supplies and products are sourced from a country with lower or affordable labor and production cost. This procurement system is utilized by many companies as a means to significantly cut or reduce expenses in order for them to maximize profit and savings. Ideal low-cost sourcing countries are China, South East Asia, Eastern Europe, India, Mexico and Turkey. Listed below are tips on how to improve and ensure the Low-Cost Country Sourcing process:

Learn about taxes: If you are trying to source your raw tools and materials from low-cost countries, you might want to take into consideration the relevant costs that come with it. When it comes to low-cost country sourcing, it is composed of tax, tariffs, legal requirements and transportation fees.

Manage a cost-benefit analysis: While you are calculating expenses, make sure to conduct a cost-benefit analysis to optimize your decision-making process. In this procurement analysis, be attentive when it comes to custom procedures and unexpected fines and expenses. One must determine practical ways to transport goods and raw materials efficiently from low-cost countries.

Evaluate the Economic Order Quantity (EOQ): Reckon with the EOQ delta; this is designed to perceive the optimal order quantity so that businesses can cut-off and minimize on their expenses, such as logistics and warehouse costs. Sustainable procurement is prioritized in order for companies to manage their listings and inventory efficiently, especially during periods of high and low demands in the market.

Assess constantly and make sure quality is up to standard: Although reducing costs and being mindful of your savings is crucial, it is also important to be reasonable. Maintaining an adequate quality of the product and fulfilling the satisfaction of your clients and customers are equally essential. With an inconsistent performance and poor quality of products from the supplier, this could cause conflicts and threats to the company’s savings.

Evaluate and foresee potential costs and circumstances with the supplier: A lot of things must be taken into careful consideration when it comes to supplier sourcing. A few of those factors are making sure that your supplier is adequate in following the contract, delivery deadlines, pricing and assures the quality of the materials and products. You have to evaluate and foresee the potential risks and costs if your supplier fails to meet your agreement or deadline, in order for you to avoid making emergency purchases.

Research over possible fluctuations in the region: Political and economical conflicts could arise anytime in low-cost sourcing countries that could influence the logistic networks and the production of raw materials itself.

Overall, with the vast development of countries and higher rate of demands, the procurement of goods from low-cost countries has caused companies to broaden their market and even increase in competition. Low-cost sourcing also requires expertise, time, understanding of cultures, laws, taxes, trends and trading, both local and overseas. Along with this, one important factor of low-cost sourcing is having a stable and progressive relationship between the companies and suppliers to ensure that there are no shortages and delays.